Product Details

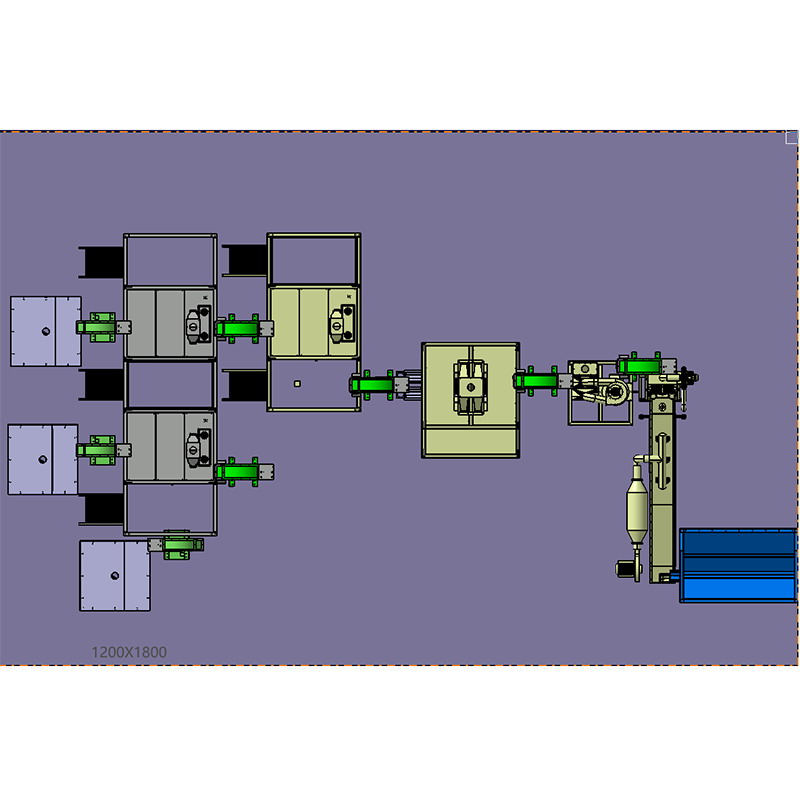

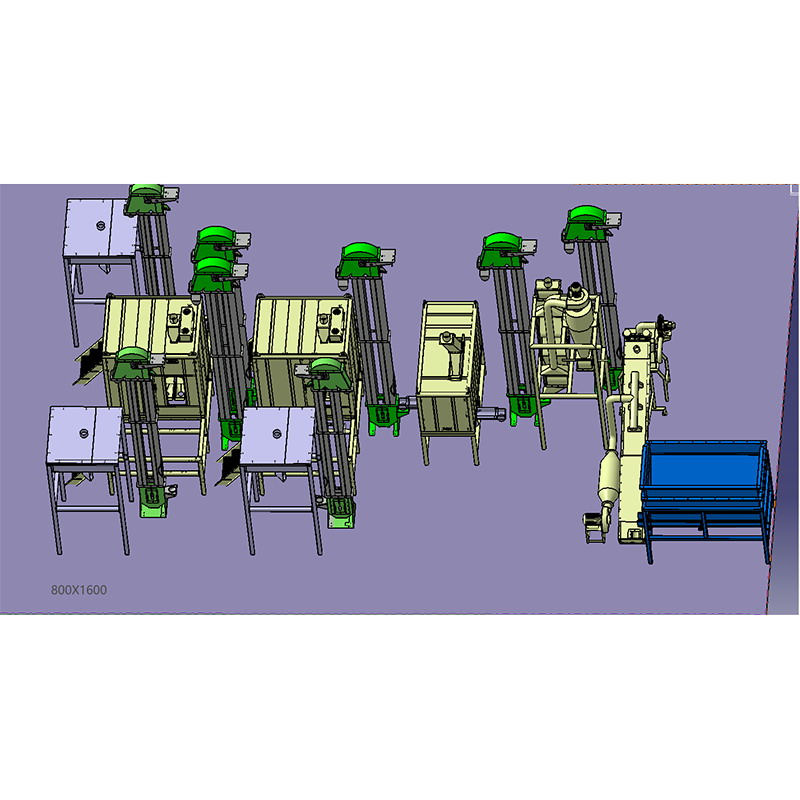

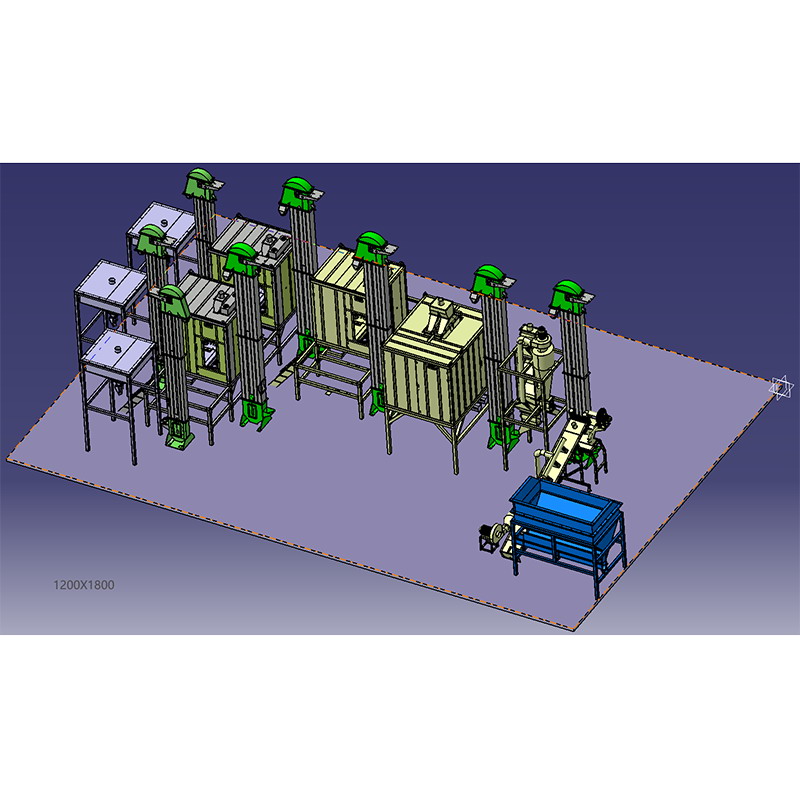

Product name: Electrostatic separation equipment

Electrostatic separators are mainly used in: resource recycling parks, waste home appliance dismantling, small home appliance disassembly and recycling industries, waste plastic recycling and other industries to sort ABS/PS/submerged PP, ABS/ABS alloy/PC, PS/PET/PVC, PA/PE/PO, etc.

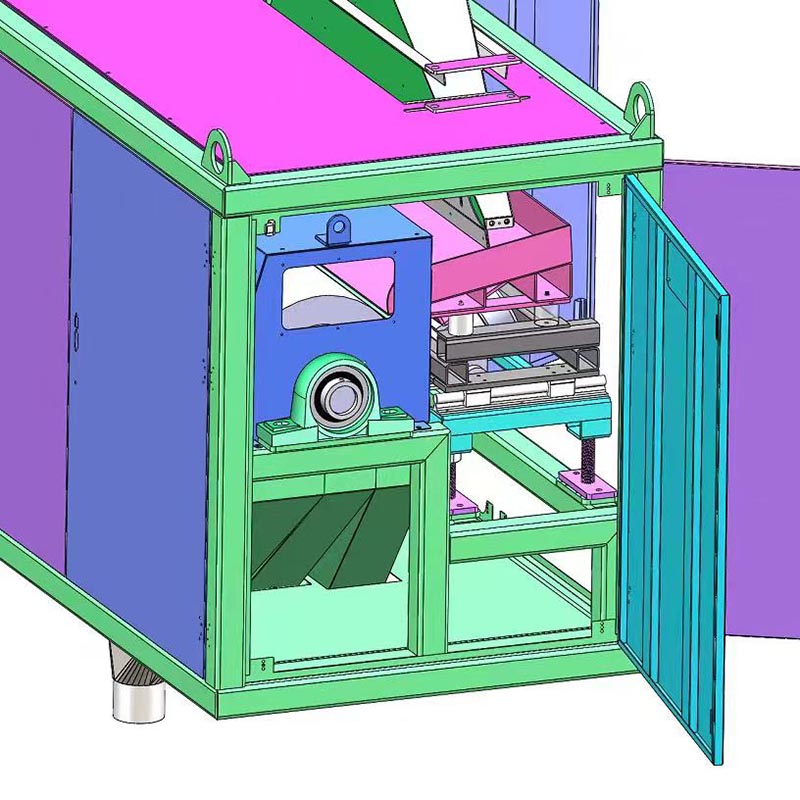

Principle: The electrostatic separator uses the difference in frictional charge of plastics to sort and classify 2-3 different types of mixed plastics through high-voltage electrostatic adsorption.

Features: Intelligent separation, ultra-high purity, efficient separation, safe and stable

1. Intelligent control: The control part uses Siemens PLC and corresponding touch screen. The operation is simple and clear. The operation is simple and saves workers, and one person can operate it.

2. Separation purity: The accuracy of the first separation of broken particles can reach 98%, and the output of 1-4.5 tons can be customized.

3. Electrostatic separation: Separate 2-3 different types of mixed materials by electrostatic means. Output: 1000KG/H

4. The equipment is made of thickened materials, which is sturdy and durable.

5. Save energy and electricity, use high-efficiency energy-saving motors

6. Environmental protection: Pure physical sorting, no need to add chemicals, no environmental pressure.

Advantages: One-time machine, fully automatic intelligent plastic separation. High-purity sorting, efficient separation, multi-stage sorting, energy saving, stable performance, quality assurance.