Product Details

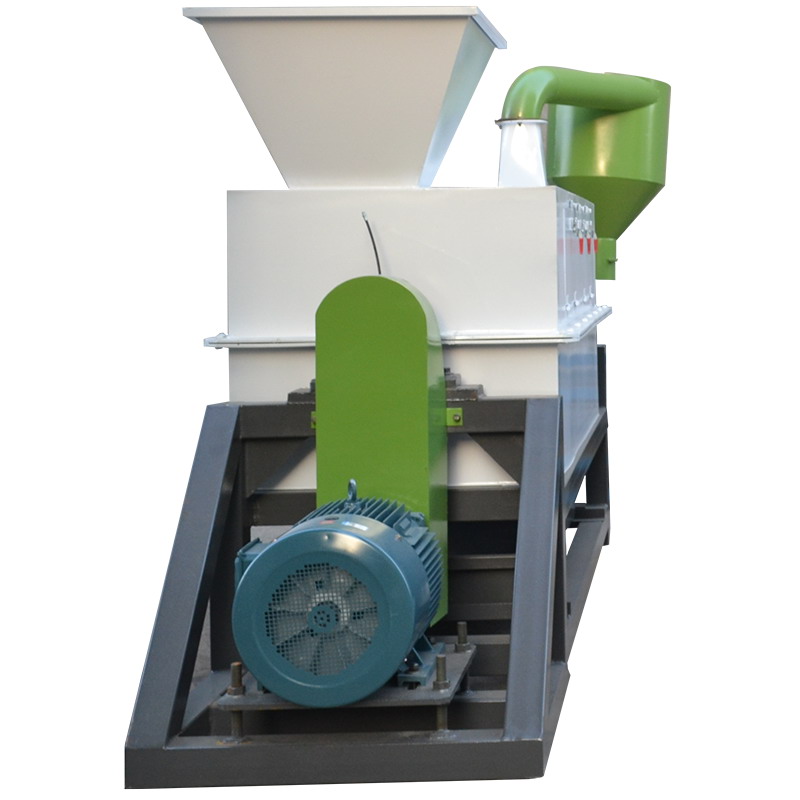

Product name: PET bottle label removal machine

For materials: plastic labels such as beverage bottles, haha bottles, PET bottles, etc. Can be used for bottle bricks and bulk bottles.

PET bottle label removal machine consists of two major parts:

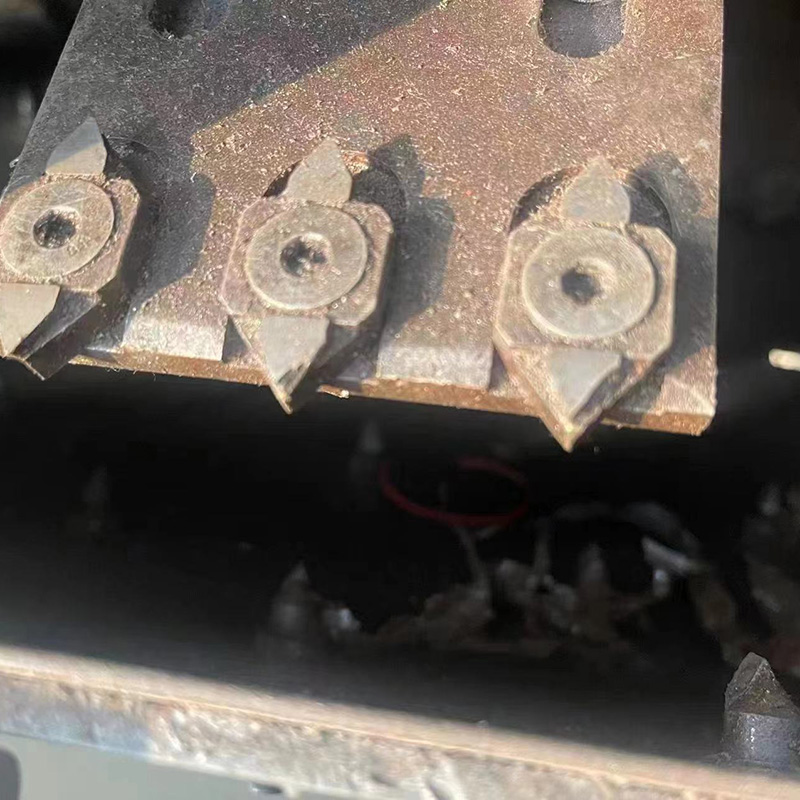

The label stripping process consists of a label stripping cylinder, a main shaft, a moving knife on the shaft and a fixed knife on the cylinder wall. All the core components are made of diamond and welded on the blade using powder metallurgy technology. The blade becomes sharper during use and leaves fewer scratches on the bottle. The blade is wear-resistant and hard. The label is stripped off the bottle through contact with the moving knife and the fixed knife during the advancement of the bottle in the machine. The separation process mainly consists of a separation cylinder, a main fan, an auxiliary fan, and a spiral air duct, and separation is performed by wind. It is highly efficient, energy-saving (no water required), convenient, and easy to maintain on a daily basis. The label stripping rate is as high as over 98%.

This machine is mainly used in conjunction with the PET bottle recycling, crushing and washing line and is generally not used alone.

|

Product Model |

YX-TB500# |

YX-TB650# |

YX-TB800# |

YX-TB1000# |

|

Specifications and dimensions (mm) |

Φ500*L5000 |

Φ650*L5000 |

Φ800*L5000 |

Φ1000*L5000 |

|

Motor power (KW) |

15kw+3kw+1.5kw |

18.5kw+3kw+1.5kw |

22kw+3kw+1.5kw |

30kw+5.5kw+1.5kw |

|

Number of blades |

110 tablets |

128 pieces |

140 tablets |

158 pieces |

|

Equipment output (KG) |

800-1000KG/H |

1000-1500KG/H |

1500-2000KG/H |

2500-3000KG/H |

|

Dimensions (mm) |

L5200*W1600*H2800 |

L5200*W2000*H2800 |

L5200*W2500*H2800 |

L5200*2800*H2800 |

|

Machine weight (T) |

1.8T |

2.5T |

3.5T |

4.2T |